Pintejin – Top China Investment Casting Shop

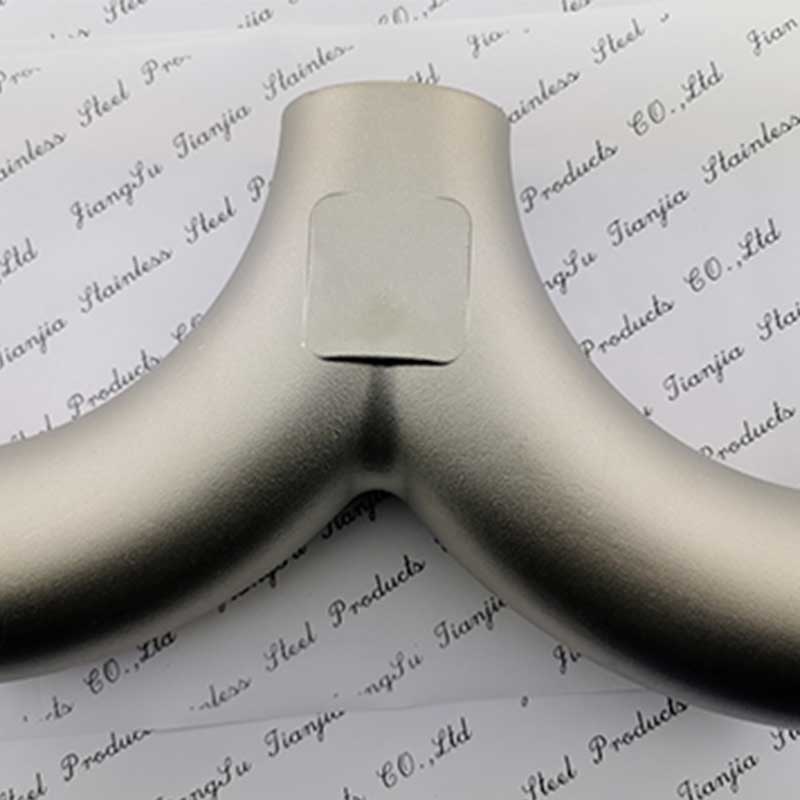

Various mechanical parts, auto parts, lock parts, valve castings, pipe joints, kitchen hardware, bathroom hardware, lighting hardware, marine hardware, architectural decoration hardware, door hinges, stair handrail accessories, glass connectors, electrical hardware castings produced by Pintejin , stove accessories and many other fields.

Pintejin have professional equipment&excellent technology. Use a professional perspective&vision to create high-end quality [precision casting] products. Recognized by global project users!

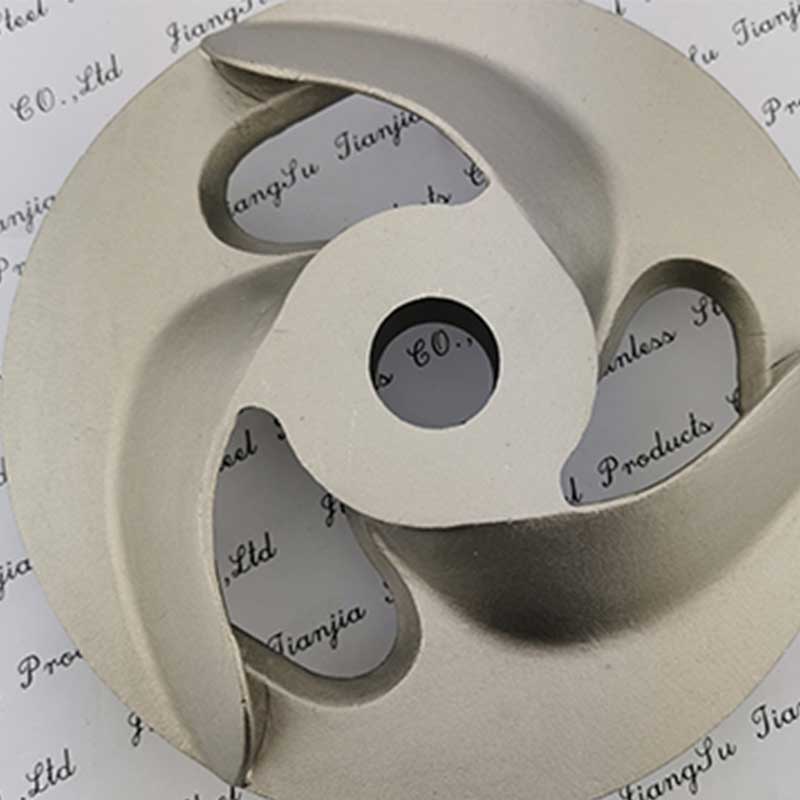

Silica Sol Precision Casting

[Silica sol precision casting] process is an excellent process technology in the foundry industry. Silica sol precision casting process casts high-quality metal castings, sewing castings, textile castings, carbon steel castings, lock castings, auto parts precision castings, stainless steel castings and other high-quality products. Because silica sol is a high-quality binder used in investment casting, it is a colloidal solution with a light blue or milky appearance; the performance of silica sol is stable and the storage period is long; the surface quality of silica sol shell is good, and high temperature strength is high. , thermal shock stability (resistance to rapid cooling and rapid heating) is good; high temperature deformation resistance is strong.

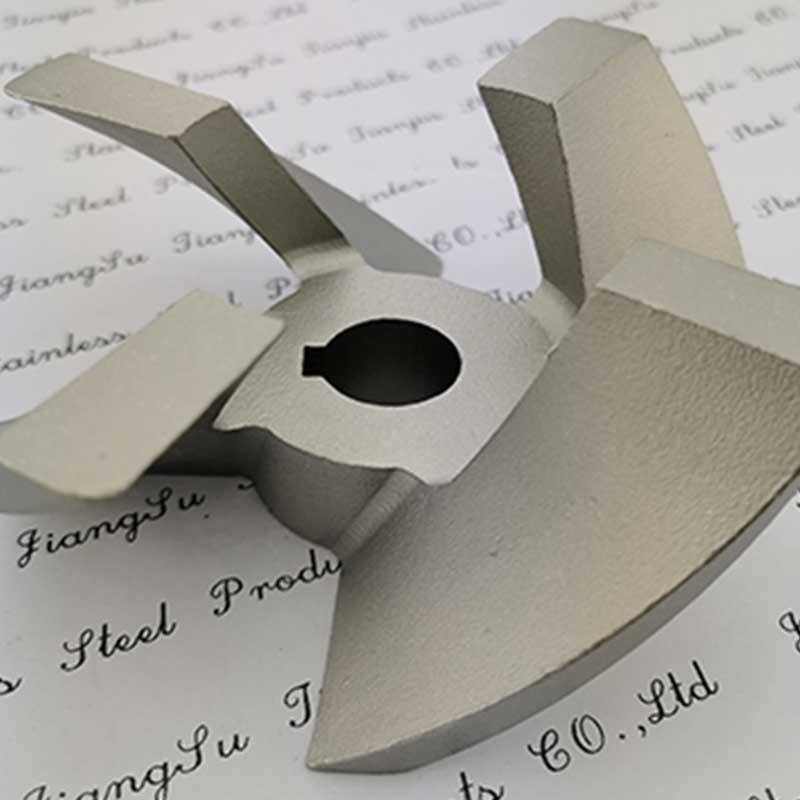

Carbon Steel Precision Casting

【Carbon steel precision casting】Adopt advanced silica sol precision casting process, with a complete set of advanced equipment and material composition testing instruments. The whole process of processing products from wax melting, injection, dewaxing, roasting and casting is automatically controlled. The molten steel with different materials in each furnace is used for on-site material composition determination and analysis with a spectrum analyzer. Casting is not allowed if the material composition is insufficient or too high, which fundamentally guarantees the quality and reliability of the product. Carbon steel precision castings are suitable for machinery, aviation, ships, automobiles, petrochemicals, communications, sports equipment and other industries.

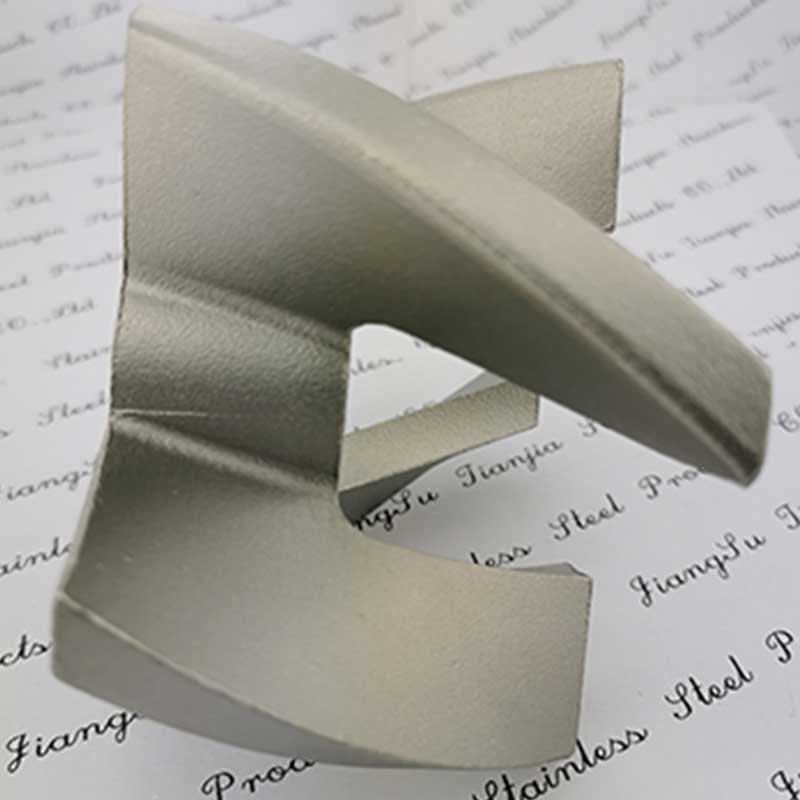

Lost Wax Investment Casting

It is mainly composed of mold manufacturing, wax mold manufacturing, shell mold manufacturing and subsequent drying, roasting, pouring, solidification and other processes. Wax is a special material for making part casting molds in investment casting, and it is one of the important factors that determine the dimensional accuracy and surface finish quality of castings. [Investment investment casting] The process refers to making a model with wax, wrapping a layer of refractory materials such as clay on the surface, heating the wax to melt and flow out, so as to obtain an empty shell formed of refractory materials, and then pouring the metal into the cavity after melting. After the metal is cooled, the refractory material is crushed to obtain a metal casting mold.

Investment Casting China – Aluminum Investment Casting Service

Pintejin Casting (under Pintejin Group) is a low-carbon and environmentally friendly manufacturer specializing in the production of various [precision castings]. The aluminum gravity castings, silica sol precision castings, carbon steel precision castings, stainless steel castings, textile castings, sewing machine castings, auto parts precision castings, sewing castings, lock castings and agricultural machinery hardware castings are all made of carbon steel and silicon. Sol precision casting process.

Pintejin Casting is mainly based on green casting. It is a large-scale investment casting, investment casting, wax casting, precision casting, lost wax casting, precision casting, lost wax casting, precision casting, steel casting and carbon steel casting in China. A professional manufacturer of precision castings.